Organization Overview

Morgan County Prison is a 377,000-square-foot correctional facility located in Fort Morgan, Colorado. The facility houses up to 325 detainees and operates 24 hours a day, 365 days a year.

Built originally in 1898, with expansions over the decades, the complex now includes:

- HVAC chillers

- Pumps and motors

- Laundry operations

- Cafeteria facilities

- Security systems

- Automation controls

- Electronics and computer systems

- A 200+ kW solar installation

As a mission-critical public safety facility, reliability, resilience, and energy efficiency are essential.

The Challenge

Correctional facilities are among the most electrically demanding building types. Morgan County Prison faced:

- High peak demand charges

- Variable and constantly changing electrical loads

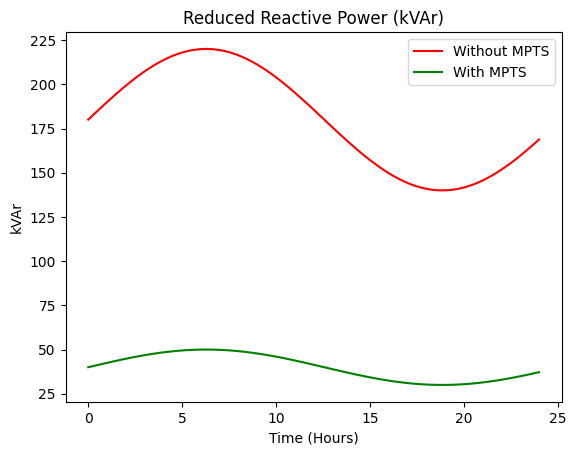

- Harmonics and transient voltage issues

- Stress on motors, pumps, and HVAC equipment

- A 24/7 operational requirement with no tolerance for downtime

Even with existing conservation measures and solar generation, inefficiencies in the electrical network were driving unnecessary demand and increasing operating costs.

The Facilities Director, known for exploring innovative efficiency technologies, first encountered MPTS in 2012. After due diligence and demonstration, the county installed its first MPTS unit in the county office.

The results were strong enough that in 2020, funding was approved for an additional MPTS installation at the prison complex.

The Solution

In June 2020, Morgan County Prison commissioned the MPTS (Maximum Power Transfer Solution) system within its electrical network.

MPTS was installed to improve power quality and optimize real power usage across the facility’s complex load profile.

Unlike passive monitoring systems, MPTS:

- Reduces total electrical demand (kW)

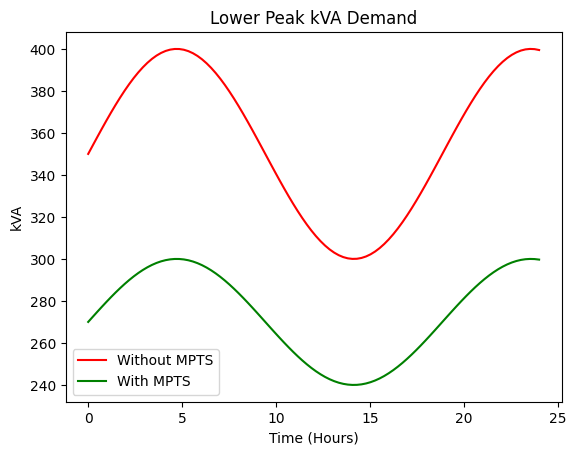

- Lowers total kVA (generation requirement)

- Mitigates harmonics

- Reduces transient voltages

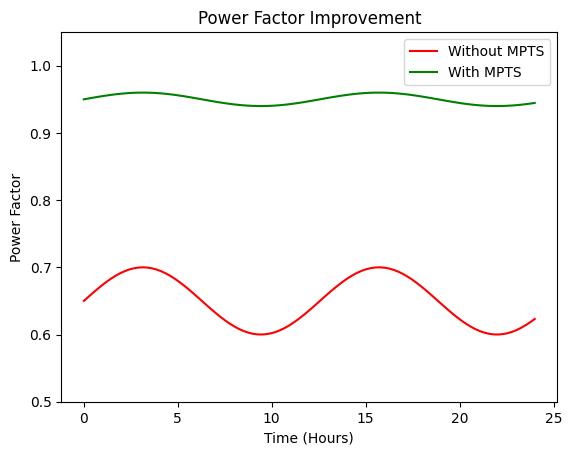

- Improves power factor

- Cleans and recycles wasted electrical energy within the network

The system was installed with:

- No operational interruption

- No mechanical retrofits

- No replacement of existing equipment

- Zero maintenance requirement since commissioning

The Results

The performance has been measured and verified by two independent metering systems:

- Accuenergy metering system

- MPTS Power Management & Metering System

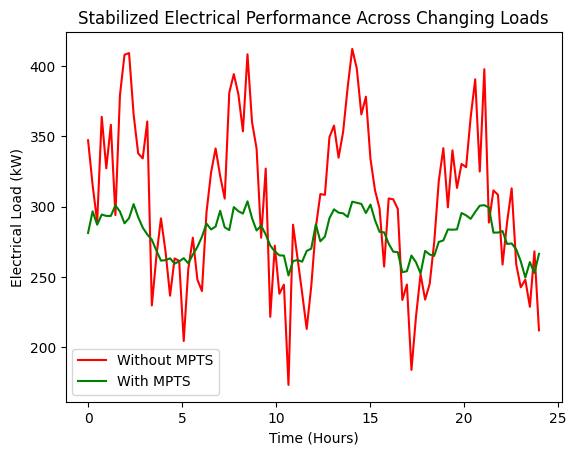

Peak Demand Reduction

- 30% reduction in Peak Demand

- Average 70 kW reduction compared to benchmark

- Over 70 kW savings at any given moment in a 24-hour operation

For a continuously operating prison, this represents sustained, measurable cost reduction — not just momentary efficiency gains.

Electrical Efficiency Improvements

The six-month performance graphs (2022–2023) show consistent performance across varying seasonal demand, proving long-term stability — not short-term anomaly

Carbon Footprint Reduction

EPA greenhouse gas equivalency calculations (shown in the report) demonstrate:

435 metric tons of CO₂ reduced

Equivalent to:

- 96.7 gasoline-powered passenger vehicles driven for one year

- 1,114,026 miles driven by an average gasoline vehicle

- 48,899 gallons of gasoline consumed

- 42,688 gallons of diesel consumed 17-Morgan-County-Prison-case-st…

This reduction occurs without replacing equipment — simply by improving how electricity is used inside the building.

Key Performance Metrics

| Metric | Before MPTS | After MPTS | Improvement |

|---|---|---|---|

| Peak Demand | High | 30% Reduction | Major Utility Savings |

| Energy Demand | Benchmark | -70 kW Average | Continuous 24/7 Savings |

| Power Factor | Variable | Significantly Improved | Higher Efficiency |

| kVA Load | Elevated | Reduced | Lower Generation Requirement |

| Harmonics & Transients | Present | Mitigated | Greater Reliability |

| CO₂ Emissions | Baseline | -435 Metric Tons | Sustainability Impact |

Operational Benefits

In addition to energy savings, the installation delivered:

- Improved electrical network resilience

- Reduced mechanical and electrical stress

- Better performance under changing loads

- Enhanced reliability for mission-critical systems

- Long-term maintenance-free operation

For a correctional facility, reliability is not optional — it is operationally critical.

Why This Matters

Morgan County Prison demonstrates a powerful reality:

You don’t have to replace equipment to unlock capacity.

By cleaning and recycling wasted electrical power within the building, MPTS reduces:

- Electrical demand

- Generation requirement (kVA)

- Carbon footprint

- Infrastructure strain

All while increasing resilience.

In a 377,000 sq. ft. 24/7 facility, even small improvements compound. A consistent 70 kW reduction becomes transformational.

Ideal Applications

Morgan County’s results are highly relevant for:

- Prisons & Correctional Facilities

- Hospitals

- Data Centers

- Municipal Buildings

- Schools & Campuses

- Water & Wastewater Plants

- Industrial Facilities

- Solar-integrated complexes